Meet our Team: Q&A with Onboarding Expert Özgür

Hello Özgür! Can you introduce yourself and your role?

Özgür: Sure! I am Özgür and the Onboarding Expert at th data. I am in charge of the training, the planning of our implementation projects, and the onboarding process for users of our Production Planning & Control system planeus.

My task is to guide our users through their onboarding processes and help them know how to use their planeus system best. I am also responsible for the design of the training material and the long-term contact person for continuous development.

We know planeus is a user-friendly and intuitive solution – So why do users still need to go through the onboarding process to use the system?

Özgür: That’s a good question! planeus is built with user-friendliness and intuitive operation in mind. Within the 14-day free trial, planeus already shows users the way to significantly improve their workflows and smart production planning with almost zero training.

However, without our onboarding process, users would not have the know-how to correctly fit planeus into their productions. To effectively use planeus, we work with our users and ensure that their production process is plannable at various levels. This means understanding the production process and structure, setting clear goals for optimization, and identifying the specific features and functionalities they need.

That’s why it is absolutely crucial to have an onboarding process in place so manufacturers can effectively utilize the system and reach their desired outcomes.

Can everyone use planeus the same way?

Özgür: Most of the time, the planeus system would need to be custom-fitted. Because every industry and manufacturing process is different, each manufacturer has their own set of objectives that they want to achieve.

For example, a manufacturer of complex machinery will have a production process, BOM structures, as well as business workflow different from a manufacturer of injection molding components. Therefore, they also need a set of specific goals to define their optimal production planning.

Additionally, a new solution needs acceptance from workers. The transition from a paper-based system to a digital one is significant for all, and if they are not ready for the changes, the transition can be difficult and disruptive. That’s why we often infuse change management together with our onboarding process.

Change management? Can you explain it to our readers?

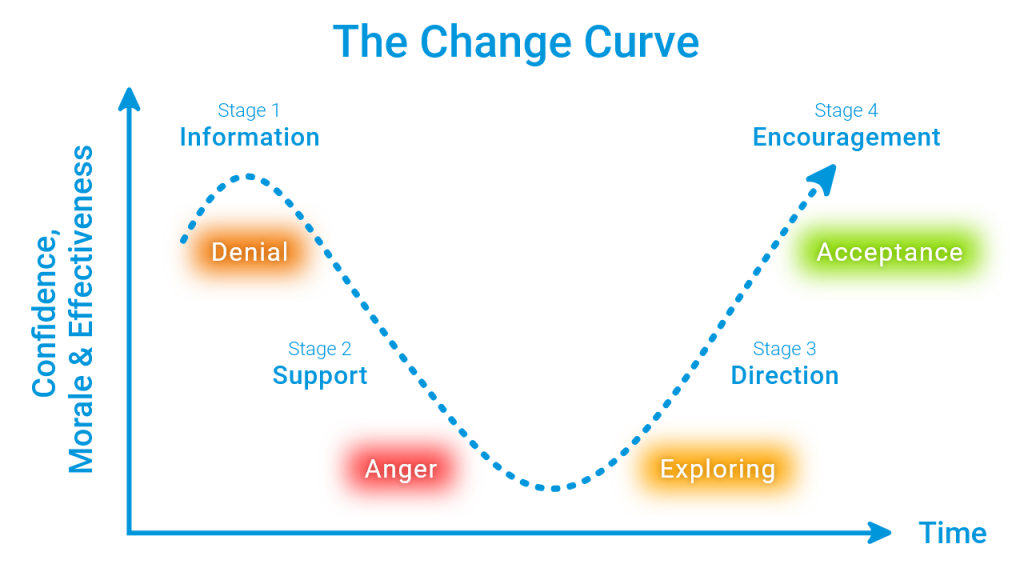

Özgür: Of course. One of my favorite examples of change management is the Kübler-Ross Change Curve. It describes the stages people go through when faced with change, including Denial, Anger, Exploring, and Acceptance.

How does this help the users smoothen their onboarding experience?

Özgür: With effective change management, we anticipate and address potential internal resistance to change. So we can provide the necessary support and resources to help our users successfully adapt to the new system and methodology.

Here, our onboarding team is able to reduce negative impacts on productivity or morale and ensure the organization is able to fully utilize the new system, making sure it’s worth every penny that they spent.

That’s quite a lot of thoughts behind the process!

Özgür: Indeed! After all, we have at least 20 years of experience in this. We know quite a lot about the stumbling blocks that could be on our users’ way to transform their production digitally.

From initial onboarding to a complete understanding of the system, we guarantee comprehensive support to our customers at every step of the way.

With our clear and flexible plan in place, our users will never be left alone, and we make sure this process is as smooth and stress-free as possible.

Can you share with us the process the users go through?

Özgür: For most planeus users, there are four main steps in the onboarding process.

- Deployment

This is our first step to kick-off the project and develop a plan that outlines the goals and targets for the implementation process. - Onboarding

Once the project is in place, our users will undergo Basic Training on how to use the mock-up system, including an introduction to the target/actual concept. - Practice

After the initial training, users will then practice using the actual system by configuring it according to their specific needs. This process is tailored to each industry as they have their own unique ways of planning and structuring their operations. This will be followed by the Go-Live, where the customer’s planeus system is in full action. - Optimization

After the Go-Live, we will keep a close relationship with the users and work on continuous development, ensuring that our solution meets the changing needs of the users and their industry.

It is a very well-thought-out process with great methodology!

Thank you Özgür for sharing!

Özgür: No problem at all. I hope it gives better insight for manufacturers who are considering digitally transforming their production – We’ve always got the back of our users on their way to success!