Overcome production bottlenecks to secure profitability in mechanical engineering

22. February 2024 | Reading Time: 6 min

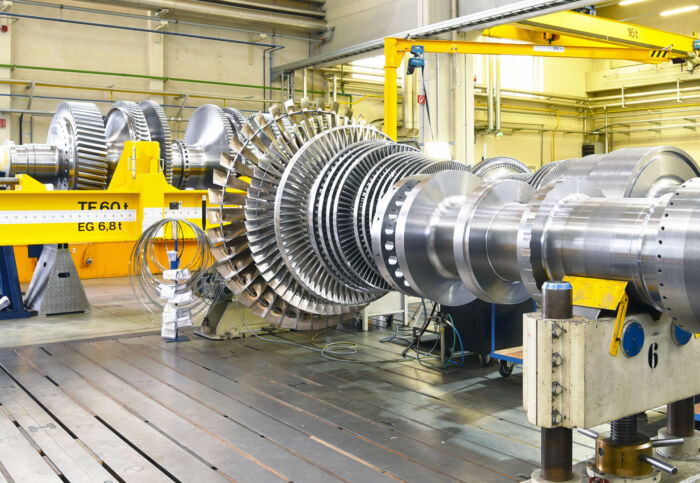

Mechanical engineering processes, particularly in plant and machinery construction, are highly interdependent. That means any unexpected disruptions, inefficiency, and planning mistakes can significantly hurt productivity, trigger delays, and have costly…