Feature Study Cycle Planning: for testing & Manufacturing Industry

20. March 2025 | Reading Time: 3 min

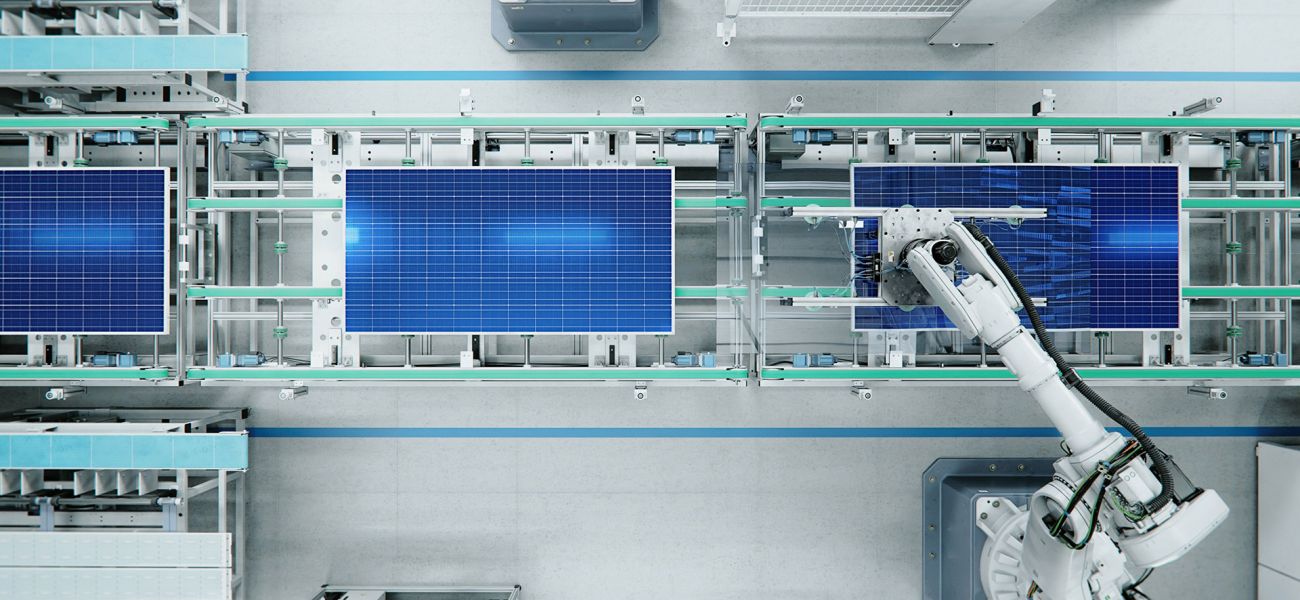

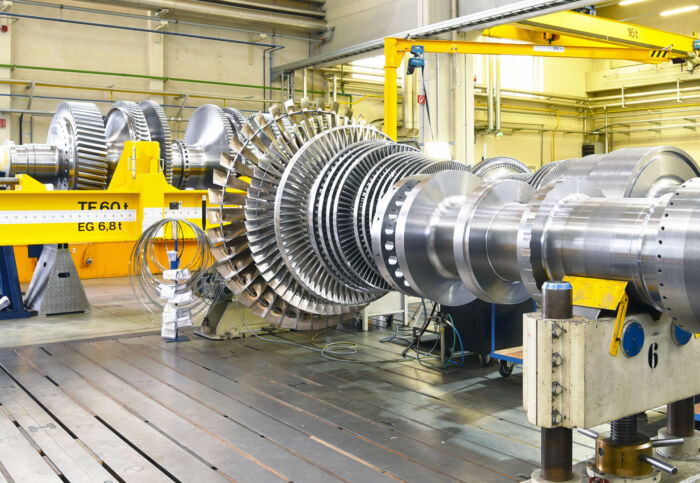

In the Life Science industry of testing and manufacturing, precise workflows and compliance with testing regulations in various countries are crucial for quality and regulatory adherence. This is particularly challenging…